We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Laurel's inner strength is our relationships with customers and employees. The heart of which is to involve all of the employees to participate in all important decisions involving the company's operation.

In the late 90’s, a unanimous concern among employees was the lack of storage space. That would lead to the dawning of a new era in quality manufacturing and customer service for Laurel Steel.

Laurel Steel wanted to continue to supply small shops, while simultaneously becoming more efficient at fulfilling the needs of larger customer accounts. To do so, we needed to solve the issue of increased inventory levels and lack of sufficient floor space.

Always considered an innovator in our field, we knew we had to make some major capital investments to be competitive in the Just-In-Time (JIT) industry.

In order to remain competitive, Laurel needed to find a way to increase manufacturing capacity within our existing facility while managing inventory more efficiently.

We viewed the project in a different way and considered cubic feet of storage, rather than just square feet. We then began to evaluate how we could double our inventory storage while cutting the required floor space in half.

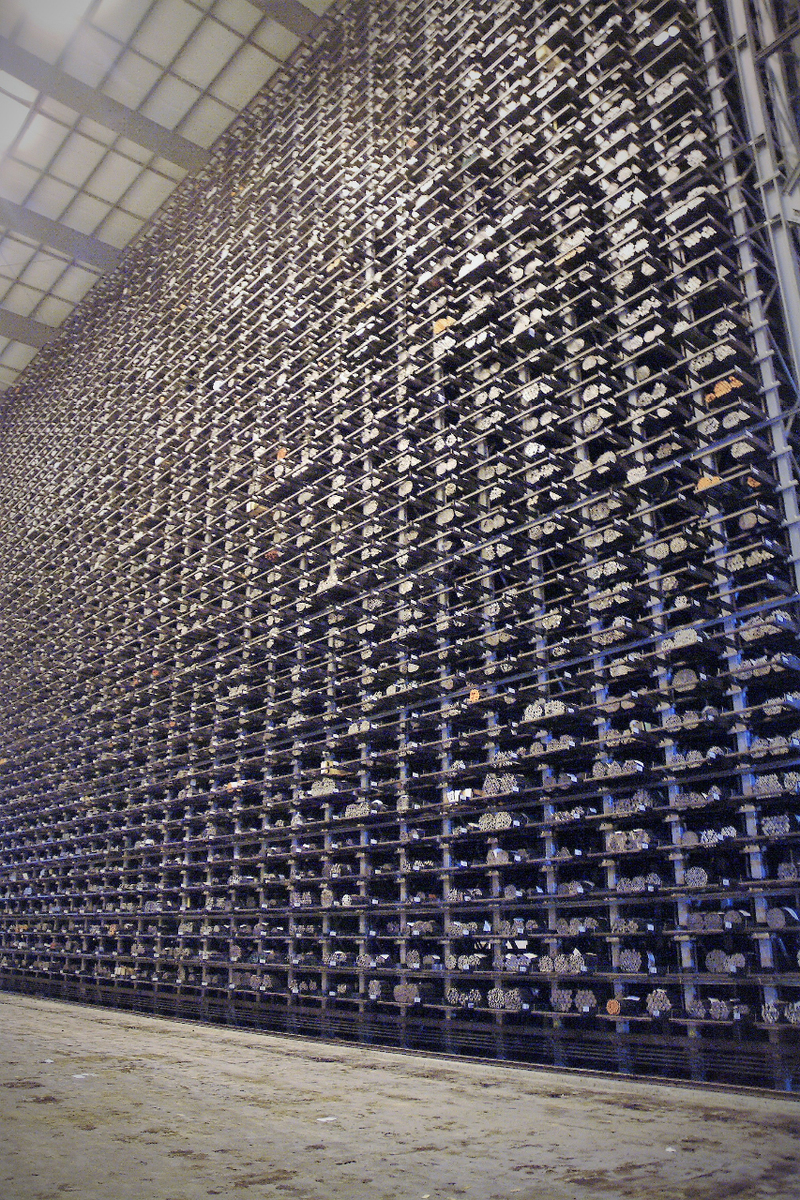

The solution would come from a manufacturer of automated high density storage and retrieval systems, named Kasto. The Kasto Honeycomb Bar Storage System would allow for superior space utilization on the smallest footprint, while implementing a computer storage system using barcode technology.

Kasto's unique compact footprint and vertical design would minimize the floor space needed for storage. The system can also provide considerable increases in product availability and overall productivity.

First, a 95-foot high bay was constructed to accommodate the 85-foot high storage system, the largest ever engineered by Kasto. This particular Kasto system can hold 2,300 storage cassettes with a load capacity of 7.3 metric tons.

The tight dimensions of two gantry cranes, one on each side, ensures optimal crane movements combined with saving as much space as possible for storage.

The system allows workers to load bundled product into a steel cassette from one of the several commissioning stations. Those cassettes are automatically fed into the Kasto storage system by one of two gantry cranes.

In order to maximize loading and unloading times, each gantry is equipped with two simultaneously working cassette pulling devices. The gantry cranes move quickly, with speeds of 328 feet/minute.

The Kasto system also employs a random storage location principle that further increases overall speed. With the help of the Kasto storage computer and barcode readers, inventory can be updated on a real-time basis. Pick times are reduced from 5-10 minutes, to only 40 seconds.

The Kasto system is completely enclosed with a safety barrier, making the entire area a fully automated, lights out warehouse. The quality of our inventory is protected by double heaters lining the building, with the entire area regulated by humidity controls. This eliminates condensation forming on the inventory, which is the main cause of corrosion.

The Quality of Our Steel Products Begin

with the World’s Finest Steel.